Inside the Power Core: Why a Servo Drive Hydraulic Pump Is Changing Industrial Systems Forever

You’ve likely watched the industrial world shift over the past few years. Machines have gotten smarter. Efficiency of hydraulic internal gear pumps has become non-negotiable. And expectations around precision, noise levels, and energy savings? They’ve skyrocketed. Now, you’re standing at a crossroads — your equipment needs to be modernized, and your next upgrade could define your entire system’s performance for the next decade.

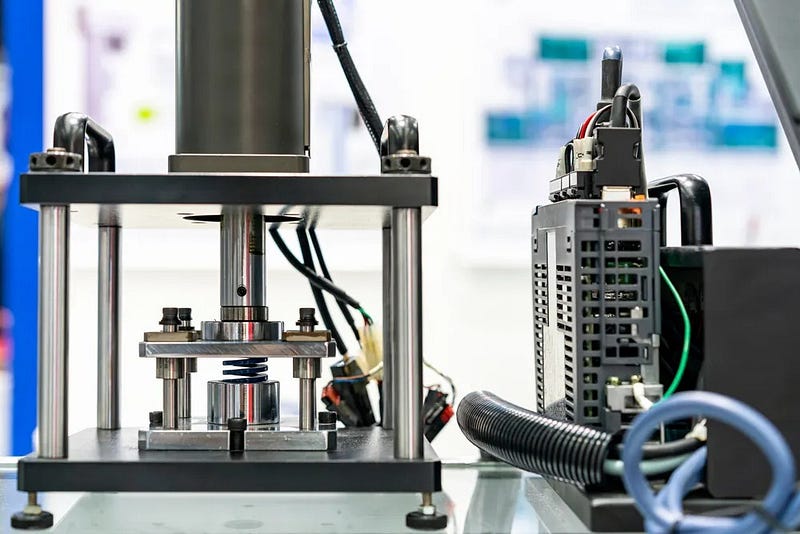

That’s where the servo drive hydraulic pump enters the conversation. This isn’t just another piece of hardware — it’s a technology that redefines how hydraulic systems deliver power. But it doesn’t work alone. It thrives as part of an ecosystem — an ecosystem that includes feedback sensors, hydraulic internal gear pumps, small hydraulic motors, and load sensing proportioning valve brake systems that all come together to create smart, responsive machines.

This post isn’t about specs. It’s about real-world impact. You’re going to explore how the servo drive hydraulic pump works, where it fits in your system, and why it offers serious ROI — not just in uptime but in long-term value and performance.

What Is a Servo Drive Hydraulic Pump and Why Should You Care?

At its core, a servo drive hydraulic pump is about intelligent motion. It uses a servo motor to control the speed of a hydraulic pump, which in turn precisely manages the flow of hydraulic fluid. Unlike traditional fixed-speed motors that run at full tilt whether needed or not, a servo-driven pump delivers just enough energy to match the system’s real-time demand.

Think about a CNC press brake system. One moment it’s idle, the next it’s moving a hydraulic ram with exact force and speed. The servo drive pump adjusts instantly to these fluctuations. You save energy, reduce noise, and avoid overheating — three pain points of legacy systems. This ability to “think and respond” makes the servo system revolutionary.

But what brings this technology to life is how it integrates with other key components of a smart hydraulic setup.

The Supporting Cast: Internal Gear Pumps and Small Motors

No system is complete without its supporting elements. The hydraulic internal gear pump, for instance, is perfect for pairing with servo drives. Why? Because it’s compact, runs quietly, and handles variable speeds extremely well without cavitation or pulsation issues. The smooth, low-noise performance of internal gear pumps makes them ideal for industrial environments where precision matters — think medical equipment, packaging lines, or injection molding.

Then come the small hydraulic motors. When you’re designing for compact automation, these motors offer just the right torque in tight spaces. Pairing them with a servo drive hydraulic pump ensures they receive optimized fluid flow — so every movement is smooth, precise, and repeatable.

These motors are a hidden powerhouse in applications like conveyors, robotic arms, or agricultural equipment. And when they’re fueled by a servo-based system, they work better, last longer, and consume less energy.

How Load Sensing Valves Fit Into the Picture

Let’s add another layer: the load sensing proportioning valve brake system. This component plays traffic cop in your hydraulic circuit. It senses load pressure and adjusts flow accordingly, making sure your actuators only get the exact force they need — no more, no less.

Pair this with a servo pump, and you’ve got a system that anticipates and adapts on the fly. A heavy lift? The valve opens wider. A precision movement? It throttles flow back down. Your machine becomes smarter, faster, and safer — all at once.

And you? You get fewer system failures, fewer emergency repairs, and a smoother, more responsive machine across every application.

The Intelligence Layer: Sensors and Real-Time Feedback

Now imagine a linear position sensor for hydraulic cylinders giving real-time data on piston location. This data feeds into your controller, which tells the servo drive how much pressure is needed at every stage of motion.

With this setup, you’re not guessing — you’re operating based on hard data. Want to maintain perfect repeatability in a high-volume stamping press? Easy. Trying to execute complex motion patterns in a robotic gripper? Done. The servo system doesn’t just react — it anticipates.

It’s this closed-loop intelligence — powered by sensors, motors, and valves — that makes servo-driven hydraulics the future of motion control.

When Things Go Wrong: Hydraulic Cylinder Repair and Preventive Design

Every system faces downtime. Seals wear. Pistons misalign. But here’s where you get another major benefit of switching to a servo drive hydraulic pump: it protects your components by never over-delivering pressure or flow.

That means hydraulic cylinder repair becomes less frequent and less severe. Servo pumps start softly and ramp slowly, reducing fluid shock. You get longer intervals between maintenance, more predictable wear cycles, and fewer surprise failures.

Even when repair is needed, components like servo motors and gear pumps are modular — making them easier to service and less expensive to replace than older, all-in-one systems.

The Cost Factor: Understanding Servo Motor Price

Let’s talk money. At first glance, servo motor prices may seem higher than traditional motors — but that sticker shock fades when you look at lifecycle costs.

Traditional hydraulic systems are inefficient by design. They run full speed, all the time, burning through electricity and wearing out components. Servo motors, on the other hand, only run when needed. This slashes your energy bill by up to 60% in some applications.

Plus, the precision they offer reduces rework, increases throughput, and minimizes material waste. Add all of that up, and suddenly, the “expensive” servo motor becomes the most affordable part of your machine.

Hydraulic Fluid Pump Consistency and Control

None of this works without a stable hydraulic fluid pump. It’s the circulatory system of your setup — moving fluid to where it’s needed, when it’s needed. In a servo system, fluid control becomes exponentially better.

Why? Because servo motors regulate pump speed with precision. You get steady pressure, accurate delivery, and total control over your actuators. Whether you’re pressing, lifting, rotating, or pushing — a servo system with a reliable pump makes your system feel like an extension of your own hand.

That’s the kind of control that used to be the domain of pneumatics or electric actuators. Now, hydraulics can do it better — with more force and flexibility.

Conclusion: Why You Can’t Afford to Ignore Servo-Driven Hydraulics

You’ve seen the trends. You’ve felt the pressure to reduce energy costs, improve precision, and future-proof your machines. The servo drive hydraulic pump isn’t just a smart upgrade — it’s a strategic investment.

By pairing it with the right components — hydraulic internal gear pumps, load-sensing valves, small hydraulic motors, and position sensors — you create a system that’s not just powerful, but intelligent. You reduce downtime, lower your operational costs, and gain control that was never possible before.

In a world that’s moving faster, working smarter, and demanding more — your hydraulics need to rise to the occasion. And with servo-driven systems, they will.

Take your hydraulics from reactive to proactive. Explore servo-driven solutions today at THM Huade — where innovation meets motion control.

Comments

Post a Comment